EpiPhotonics pioneers and leads the design and manufacture of PLZT thin-film

waveguide technology. PLZT is one of most attractive materials for the

integration of high-channel count and/or various photonic functions into

a small monolithic chip, with high-speed control and low-power dissipation.

Its efficient, voltage-induced index change, that is, the electro-optic

effect, enable thermal cross-talk free integration, miniaturization of

electrodes, and low power dissipation. Moreover, its suitable high refractive

index (2.45) decreases the bending radius of a classic waveguide.

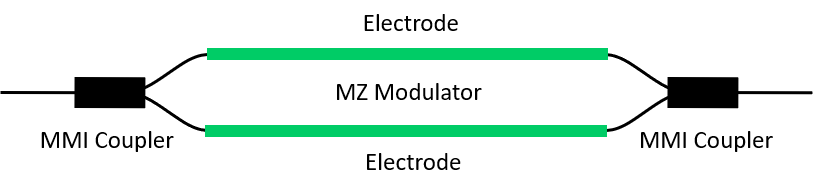

PLZT optical switches have a MMI-MZ (Multi Mode Interference-Mach Zhender)

type switch design with wavelenth insensitive nature. The PLZT growth and

the PLZT waveguide are described below.

EpiPhotonics succeeded in producing the world's

first low-loss, thin-film waveguide

by using

solid-phase epitaxy (SPE). SPE

differs from

widely used vapor-phase growth

technologies,

such as sputtering and MOCVD.

In our process,

uniquely synthesized metal organic

solutions

are applied to substrates and

heated at ambient

pressure to form amorphous films.

These films

are then heated to create epitaxial

single-crystals.

This manufacturing SPE method

is extremely

simple and eliminates the need

for large-scale

vacuum equipment, making it possible

for

drastic cost reduction.

Buried PLZT waveguides are grown on Nb:SrTiO3 semiconductor substrates in order to facilitate application of electrical field. Using this sandwiched electrode structure and combining it with PLZT's inherently high electro-optic coefficient, we have achieved drastic improvements in switching and/or modulating performances;

Buried PLZT waveguides are grown on Nb:SrTiO3 semiconductor substrates in order to facilitate application of electrical field. Using this sandwiched electrode structure and combining it with PLZT's inherently high electro-optic coefficient, we have achieved drastic improvements in switching and/or modulating performances;

- High-speed switching (<5ns)

- Low driving voltage

- Low insertion loss

- Low polarization dependence

- Low power consumption

- Miniaturization

Solid-phase epitaxial growth technology combined with our micro-fabrication

technique, guarantees huge cost reduction. Exploiting the high index nature

of our material and realizing a buried waveguide, low-loss sharp S-bends

and efficient waveguide structure are assured. This allows us to produce

very compact waveguide devices including switches, modulators, and AWGs

At EpiPhotonics, we excel in creating innovative and efficient products

based on our proprietary thin film PLZT waveguide technology based on design

and manufacturing processes refined over decades of research and development.

The devices utilizing the technology enabled us to develop high-speed integrated

subsystems with performance levels that were deemed impossible a short

time ago. EpiPhotonics's success and ability to compete depends on its

ability to develop technological expertise internally. EpiPhotonics relies

on a combination of patent and trade secret laws. EpiPhotonics' intellectual

property is protected by a portfolio of more than 50 patents, including

transferred patents from Keio University, in the United States and in Japan.

The patents portfolio covers precursor synthesis,

thin-film growth, micro-fabrication, waveguide

structure, integration on semiconductor,

and device structures.

| Nano-Second Speed PLZT Waveguide Switches

and Filters |