|

|

EpiPhotonics conducts full range of processes starting from device design, PZT

and PLZT thin film wafer fabrication in its own clean room, packaging,

and testing.

- Design: Simulators, CAD.

- Thin film deposition: RTA, Sputtering, E-beam deposition, etc.

- Microfabrication: Spinner, Aligner,

Baking truck, Asher, Dry etcher, etc.

- Post wafer: Dicer, Polisher, Wire bonder,

Fiber aligner, etc.

- Testing: Switching curve, IL, PDL, RL, WDL, etc..

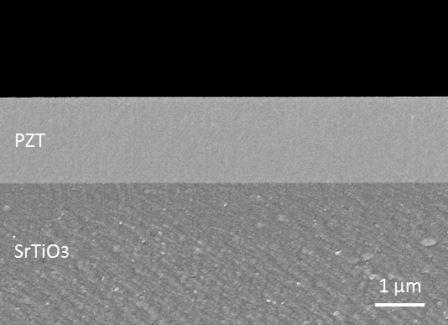

PZT/PLZT Deposition and Microfabrication

EpiPhotonics is the expert of oxide thin-film technology including PZT/PLZT

devices. EpiPhotonics provides high quality PZT and PLZT thin films based

on its unique chemical solution deposition technology for photonics and

piezoelectrics/MEMS, and microfbrication of PZT/PLZT thin films.

- PZT thin film deposition (1 um-3 um) on Pt/Ti/SiO2/Si wafers for piezoelectrics/MEMS

- PLZT waveguide deposition (3 um-8 um) on single crystal oxide wafers

- Micro-patterning of PZT/PLZT

- Metal layer deposition (Pt, Au, Ti, Cr, ITO) and patterning

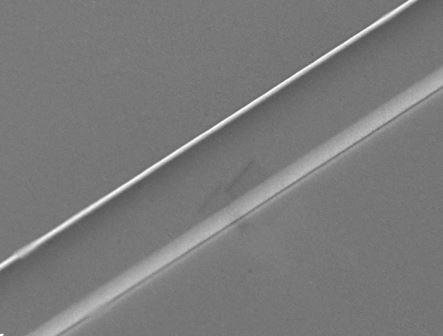

Example of epitaxial PZT thin film: cross section and etched pattern (SEM)

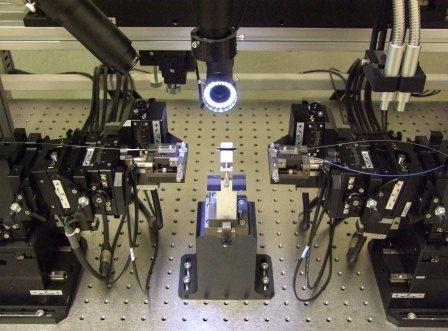

EpiPhotonics dices waveguide wafers and polishes waveguide end faces.

Pigtailing

EpiPhotonics aligns and connects optical fibers to polished waveguides.

Please contact us at sales@epiphotonics.com

for more details.

Please contact us at sales@epiphotonics.com

for more details.

|